Choose the right cutting machine to cut PPF professionally

Hi, dear wrap shop owners, are you still cutting film by hand?When it comes to Paint Protection Film (PPF), precision cutting is everything. A flawless cut enhances the film's ability to protect a car's paint, saves time, reduces material waste, and ensures a smooth application. However, many shops still rely on traditional hand-cutting methods. What’s the problem with that? Let’s dive in to see why upgrading to a professional cutter is the smartest move you can make.

The Challenges of Traditional Cutting Methods

Hand-cutting may seem simple, but it has some serious drawbacks:

Material Waste: Every roll of PPF is costly, and mistakes or inaccurate cuts can lead to significant losses. Studies show that hand-cutting can waste up to 30% of materials. Imagine throwing that much money away!

Time-Consuming: Cutting by hand is time-intensive. And time is money, especially when you have a long line of clients waiting for their cars to be wrapped.

Inconsistent Results: Even the most skilled technicians struggle to achieve consistent results across different vehicles. Those tricky curves and tight corners? They’re a nightmare for hand-cutting.

Skill Dependency: Not everyone on your team has the expertise of a seasoned technician. For new hires, it’s hard to get them up to speed without wasting materials.

Bottom Line: Hand-cutting isn’t just outdated; it’s costing you time, money, and customer satisfaction.

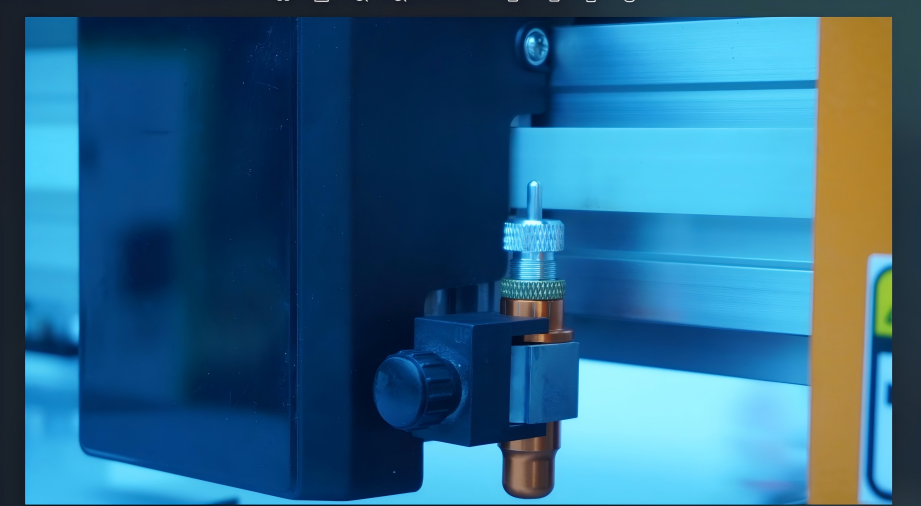

What Is a PPF Cutting Machine, and Why Does It Matter?

A PPF cutting machine is a smart, automated solution designed to cut pre-designed templates for automotive films with precision. But it’s more than just a tool; it’s the backbone of a modern PPF business.

How It Works: The machine uses pre-loaded vehicle data to cut PPF perfectly, eliminating guesswork and reducing errors.

Why It’s a Game-Changer: Forget manual adjustments! Just select the right template, press cut, and let the machine work its magic.

What It Can Cut: Beyond PPF, advanced machines can handle vinyl wraps, window tints, and even reflective decals, making them versatile investments.

Financial Impact: A high-precision cutting machine can reduce costs associated with waste and rework while also increasing throughput. Shops using advanced cutters report being able to serve more clients without increasing labor.

How to Choose the Right PPF Cutter: A Buyer’s Guide

Thinking about upgrading? Smart move! But how do you pick the right cutter? Here are the must-have features:

1. Extensive Data Compatibility

Your cutter must access the latest vehicle models. Outdated data? No thanks! With YINK’s cutters, you can tap into a database of 400,000+ car models, ensuring precise cuts every time.

Why It Matters: Cars are evolving, and staying up-to-date with the latest designs ensures you’re always prepared.

2. Cutting Precision

Look for a cutter with ultra-high accuracy. For example, a precision of 0.01mm ensures that your film fits perfectly, even on tricky car contours.

Precision Saves Money: High-accuracy machines reduce errors, which means less wasted material and more satisfied clients.

3. User-Friendly Operation

Not everyone’s a tech wizard. Machines like YINK’s 905X ELITE, equipped with a 4.3-inch touchscreen, make it easy for your team to get started quickly.

Ease of Training: Intuitive interfaces reduce training time for new employees, getting them productive faster.

4. Material Versatility

Your cutter should handle more than just PPF. The YK-903X PRO can cut window films, vinyl wraps, and even reflective decals, making it a versatile choice for any shop.

Expand Your Services: Versatile machines allow you to offer more services, attracting a wider customer base.

5. After-Sales Support

A reliable after-sales service system ensures your cutter works seamlessly for years. YINK not only provides detailed usage guides but also offers quick responses to operational issues, giving you peace of mind.

Dedicated Support Groups: YINK sets up exclusive service groups for every buyer, staffed with specialists to assist with any questions or issues.

6. Additional Features

Super Nesting: This feature optimizes material layout, reducing waste by up to 20%.

Quiet Operation: A noisy machine is a headache—literally. Silent motors create a peaceful workshop.

Portability Options: Some machines, like the YK-901X BASIC, are compact and easy to move, perfect for shops with limited space.

7. Scalability

Investing in a machine that can grow with your business is crucial. Machines like the YK-T00X Flagship Model offer advanced features suitable for high-volume operations, ensuring your business can handle increasing demand.

Why Choose YINK?

When it comes to cutting-edge PPF equipment, YINK cutters are second to none. Here’s why:

YK-901X BASIC: Ideal for beginners, this model offers excellent precision at an affordable price. Perfect for shops transitioning from hand-cutting.

YK-905X ELITE: A high-speed, ultra-precise cutter designed for professionals. Its advanced features ensure smooth operation and perfect results.

YK-T00X: The ultimate machine. This powerhouse handles PPF, tint, vinyl, and more, built for high-volume operations with a 15-month service package included.

Support

Additionally, YINK creates dedicated service groups for each buyer, staffed with after-sales specialists ready to assist. This personalized support ensures customers maximize the benefits of their machines.

Environmental Benefits

YINK’s advanced cutters are designed to minimize material waste, contributing to a more sustainable industry. This isn’t just good for the planet—it’s great for your bottom line.

Going Beyond Cutting

YINK’s equipment also incorporates features that let you customize templates, engrave logos, and even adapt designs for motorcycles or interior car parts. This adaptability opens doors to premium services and upselling opportunities.

Pro Tips for Mastering PPF Cutting

Want to make the most of your cutter? Follow these tips:

Start with Practice Runs: Use test film for your first cuts to avoid wasting expensive materials.

Adjust Knife Pressure: Ensure the blade cuts through the film but doesn’t damage the backing paper.

Use Automatic Nesting: This feature arranges patterns efficiently, minimizing waste.

Maintain Your Equipment: Regularly clean and calibrate your cutter to keep it in top condition.

Understand Software Features: Explore options like edge expansion or graphical decomposition to enhance your cuts.

Monitor Performance Analytics: Advanced cutters like the YK-T00X provide data on material usage and efficiency, allowing you to identify areas for cost savings.

Pro Tip: Check out YINK’s YouTube tutorials for step-by-step guides.

Team Training Matters

Ensure your team is fully trained to use both the machine and software effectively. Many issues arise not from the equipment itself but from improper use or lack of knowledge. YINK provides comprehensive guides and workshops to bring everyone up to speed.

The Future of PPF Cutting: Efficiency Meets Sustainability

As the industry evolves, cutting machines are becoming more efficient and eco-friendly. High-speed cutters like the 905X ELITE and T00X minimize material waste, helping shops save money while reducing their carbon footprint.

With continuous updates, YINK ensures its equipment stays compatible with the latest vehicle models, keeping you ahead in a competitive market.

Trends to Watch

Increased Automation: Machines with advanced sensors and self-calibrating features are simplifying operations.

Expanded Material Compatibility: As new films are developed, cutters will adapt to handle these materials with ease.

Data-Driven Insights: Advanced machines can provide analytics on usage patterns, helping shops optimize material usage and reduce costs.

Collaborative Networks: Shops using YINK machines can contribute to shared databases, improving access to the latest vehicle templates.

Collaborative Opportunities

YINK’s focus on collaboration means shops can share data to improve the overall database. For instance, scanning new vehicle models can contribute to the global library, ensuring everyone benefits from updated patterns.

Conclusion: Invest in the Right Cutter and Transform Your Business

Upgrading to a professional PPF cutter isn’t just a smart choice—it’s a game-changer for your shop. With the right equipment, you’ll save time, reduce waste, and deliver flawless results that keep clients coming back.

Ready to make the switch? Explore YINK’s cutting machines and see how they can revolutionize your PPF business. Because when it comes to professional cutting, the right tools make all the difference.

Remember: Precision isn’t just about cutting film—it’s about cutting costs, waste, and time. Get it right with YINK!

Post time: Jan-16-2025