Why do you need the PPF Cutting Software?

If you run an automotive shop, chances are you’re already well-acquainted with the importance of Paint Protection Film (PPF). This thin, transparent layer of film serves as an invisible barrier, protecting a car’s paint from scratches, chips, UV damage, and all sorts of environmental hazards. It’s a must-have for any car owner who values the longevity of their vehicle’s appearance. However, if you’ve been relying on the old-fashioned method of cutting PPF by hand, it might be time to ask: Does my shop need PPF cutting software?

Let’s break it down and explore why integrating PPF cutting software into your business could be a total game-changer, not just for your efficiency, but for the overall quality of your work, customer satisfaction, and bottom line.

What Is PPF Cutting Software?

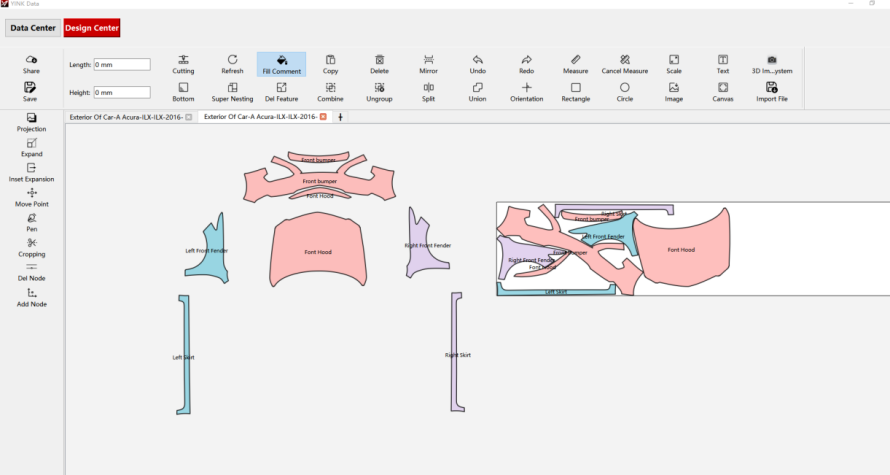

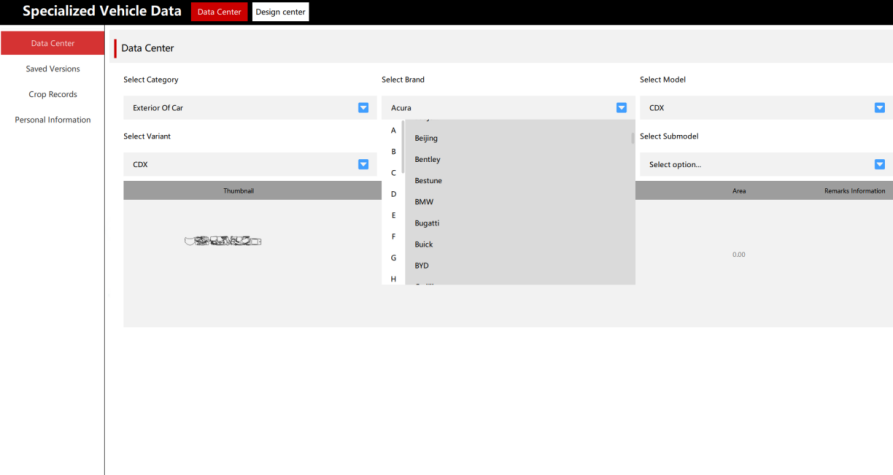

Let’s start with the basics. Before we dive into the perks, we should first understand what PPF cutting software actually is. Simply put, PPF cutting software is a specialized tool designed to help you cut Paint Protection Film into precise patterns and shapes. Instead of manually measuring and cutting the film to fit specific car models, the software uses digital templates that match the exact dimensions of various car parts. With this software, you can simply input the car model or design, and it will automatically create a template that the cutting machine will follow, making flawless cuts every time.

The real beauty of PPF cutting software lies in its ability to eliminate much of the manual labor, human error, and inefficiency that comes with traditional cutting methods. In the past, you would have had to measure every single car part by hand—no easy feat when you’re dealing with intricate curves and odd shapes. Now, you load your PPF roll, enter the car details, and let the machine handle the rest.

But wait—let’s dive a little deeper into why this software is so essential for modern automotive shops.

PPF Cutting Software Benefits: Efficiency, Quality, and Competitiveness

So, you’ve got the basic idea of what the software does, but how does it actually benefit your business? How does it make a difference in your day-to-day operations? Well, buckle up because we’re about to take a ride through the key advantages that PPF cutting software brings to the table.

Increased Efficiency: Get More Done in Less Time

We all know time is money. The faster you can cut and apply PPF to a car, the more jobs you can take on in a single day. Traditional methods of cutting PPF can be time-consuming, especially when you’re manually measuring, cutting, and adjusting the film to fit every car. And let’s be honest, you probably don’t have hours to spare on each job.

That’s where PPF cutting software comes in. The software speeds up the process by providing you with exact templates for a wide range of car models. Instead of manually measuring each curve and contour, the software does it all for you, and your cutting machine follows the pattern perfectly. The result? You can finish jobs faster, serve more customers, and keep your shop running at full throttle.

Imagine this: A busy day with several cars waiting for PPF installations. With traditional methods, you’re stuck spending at least an hour per car just on the cutting. But with the software, you can complete multiple cars in the same amount of time. Not only does this free up more time for you to focus on other aspects of the business (like marketing or customer service), but it also improves your shop’s throughput—meaning more cars, more revenue, and less downtime.

Quality and Consistency: No More Guessing

The beauty of PPF cutting software is that it’s programmed to deliver consistent results every time. In manual cutting, even the most experienced technician can make small mistakes. A slip of the hand here, a wrong measurement there, and suddenly the fit isn’t perfect. For car owners, even minor imperfections in their PPF can be a deal-breaker. After all, who wants to pay for an invisible shield that looks anything less than flawless?

With the software, there’s no room for error. Every cut is made with precision, ensuring that the PPF fits like a glove, every single time. This is particularly important when you’re dealing with high-end vehicles, where customers expect perfection. Whether it’s a luxury sports car, an SUV, or a standard sedan, the software guarantees uniformity, making it easy to apply the film seamlessly to every surface of the vehicle.

Cost Efficiency: Cut Waste, Increase Profit

If you’ve been in the PPF business long enough, you know how easily materials can get wasted during the manual cutting process. Miscalculations, poor alignment, or simply overestimating how much film you need can result in excess waste, which means more money out of your pocket.

PPF cutting software helps optimize material usage, meaning you’ll need less film to cover the same area. It calculates the exact amount of PPF required, ensuring minimal waste. Over time, this means more savings and higher profitability, especially when you’re working with expensive film.

But the benefits don’t stop there. By reducing material waste, you’re also doing your part for the environment. Less waste means fewer resources are consumed, which could even attract eco-conscious customers who appreciate your commitment to sustainability. So, not only does the software help your bottom line, but it also helps you become a more responsible business in the eyes of the public.

Speedy Turnaround: Keep Customers Happy

In the fast-paced automotive industry, quick turnaround times can make or break a customer relationship. Customers don’t want to wait days for their PPF installation. They want to drop off their car, get it protected, and go on their way as quickly as possible.

Traditional methods can be slow and leave your customers frustrated if they’re left waiting for an extended period. But with PPF cutting software, you can drastically reduce turnaround times. By automating the cutting process, you can finish the job in less time without sacrificing quality. And as we all know, happy customers are repeat customers.

The quicker you can deliver the finished product, the more likely your customers will recommend your shop to others. And the best part? A quick turnaround doesn’t mean compromising on quality. The software ensures that each cut is perfect, so you’re providing both speed and precision.

How PPF Cutting Software Helps Overcome Common Challenges

Running an automotive shop involves a constant battle against common challenges that could slow down your workflow and impact your profit margins. Let’s take a look at some of these issues and how PPF cutting software can help you overcome them:

Human Error

Let’s face it—human error happens. Even the best technicians can make mistakes. Maybe the cutting blade slips, or maybe the measurements get a little off. Regardless, these errors can lead to imperfect cuts, wasted material, and dissatisfied customers.

PPF cutting software eliminates these mistakes by providing exact templates and automated cutting. The machine doesn’t get tired, it doesn’t get distracted, and it doesn’t make errors. The software ensures that each cut is flawless, which means less rework and fewer unhappy clients.

Material Waste

Without the proper tools, it’s easy to miscalculate how much material is needed for each job, leading to wasted PPF. This can eat into your profits, especially if you’re working with high-quality, expensive film.

PPF cutting software removes this issue by calculating the precise amount of film required for each car model. This reduces the chances of overestimating and wasting material. Not only does this save money, but it also reduces your environmental footprint, making your business more eco-friendly.

Inconsistent Results

When different technicians are involved in the PPF cutting process, the quality of the results can vary. One technician might make a clean cut, while another could leave jagged edges. These inconsistencies can affect your shop’s reputation and cost you valuable customer trust.

With PPF cutting software, consistency is guaranteed. Regardless of who operates the machine, the result will always be the same: clean, precise, and perfect cuts. This ensures that your customers get the same high-quality service every time, which builds loyalty and trust in your brand.

YINK Software: The Competitive Edge for Your Shop

If you’re looking for cutting-edge software that combines all these advantages and more, YINK PPF Cutting Software is the solution for you. This software is designed to make your PPF cutting process as streamlined and efficient as possible.

One of the standout features of YINK is its Super Nesting function. This feature automatically arranges the cutting patterns for maximum efficiency, reducing material waste and ensuring that you’re making the most out of every roll of PPF. With Super Nesting, you won’t just save time, but you’ll also save money by cutting the material more efficiently.

In addition, YINK’s software is built to provide high precision. It guarantees accurate, repeatable cuts no matter the model, which is essential for maintaining the level of quality your customers expect. Whether you’re working on a fleet of standard cars or rare exotic vehicles, YINK ensures your cuts will always meet the highest standards.

When Is the Right Time to Invest in PPF Cutting Software?

You might be asking yourself, “Do I really need PPF cutting software now, or can it wait a little longer?” Deciding when to invest can feel like a big step, but there are some clear signs that it’s time to take the plunge. Let’s look at a few scenarios where making the switch to cutting software becomes a no-brainer:

1. You’re Experiencing Increased Errors

Even the best technicians have off days, and manual cutting is a process that leaves a lot of room for human error. Whether it’s a miscalculated measurement, a shaky hand, or the dreaded “Oops, I thought I measured that right,” these small mistakes can add up to big problems.

If your team is making more errors than you’re comfortable with, it’s time to let software take the reins. PPF cutting software is designed to eliminate human error, delivering perfect, repeatable cuts every single time. Not only does this save you from material waste and rework costs, but it also saves your team from the stress of constantly having to fix their mistakes.

2. Turnaround Times Are Slowing You Down

Do you find yourself apologizing to customers for delays more often than you’d like? Long turnaround times can frustrate even your most loyal clients. If your current process is struggling to keep up with demand, cutting software can change the game.

By automating the cutting process, you can drastically speed up your workflow without sacrificing quality. With software like YINK, jobs that used to take hours can now be completed in a fraction of the time, allowing you to handle more customers and increase your revenue.

3. You’re Handling More Volume Than Ever Before

Growth is great—until your tools and processes can’t keep up. If your shop has started taking on more clients, more vehicles, or larger projects, you need systems that scale with your business. Manual cutting is fine when you’re handling a couple of jobs a day, but once demand ramps up, it can become a bottleneck.

PPF cutting software is built to handle high volumes with ease. By optimizing material usage and cutting time, the software enables your shop to operate at full capacity without burning out your team. It’s the ultimate upgrade for a growing business.

4. You’re Losing Money on Material Waste

Have you ever looked at a pile of discarded film scraps and wondered how much money you’ve just thrown away? Material waste is one of the biggest hidden costs in the PPF business. Every time a cut is slightly off, or a piece doesn’t fit quite right, you’re losing valuable resources.

Cutting software minimizes waste by calculating exactly how much film is needed for each job and arranging patterns efficiently. Features like Super Nesting in YINK software ensure that every inch of your film is used effectively. Less waste means more savings—and who doesn’t love more savings?

5. You Want to Elevate Your Business Image

Today’s customers expect businesses to use the latest tools and technology. If you’re still relying on manual processes, it can give the impression that your shop is behind the times. On the other hand, investing in cutting-edge software like YINK shows your customers that you’re committed to delivering the best service possible.

High-end clients, in particular, are likely to notice and appreciate the difference. Whether they’re bringing in a luxury sports car or an entire fleet of vehicles, customers want precision, efficiency, and professionalism. Cutting software helps you deliver on all three fronts, positioning your shop as a leader in the industry.

When You’re Ready to Invest

If any of these scenarios sound familiar, it’s probably time to take the leap. While PPF cutting software does require an initial investment, the long-term benefits far outweigh the cost. Reduced waste, faster turnaround times, and happier customers all translate into higher profits and a more successful business.

Take the time to evaluate your shop’s needs and calculate your potential return on investment (ROI). In most cases, you’ll find that the software pays for itself quickly—sometimes within months. And once you start experiencing the benefits firsthand, you’ll wonder how you ever managed without it.

Common Misconceptions About PPF Cutting Software

While the benefits of PPF cutting software are clear, some shop owners hesitate to make the leap because of common misconceptions. Let’s address these myths head-on:

“It’s Too Expensive”

At first glance, PPF cutting software might seem like a hefty investment, especially if you’re running a smaller shop. But consider this: how much are you currently spending on wasted film, rework due to cutting errors, or the extra labor hours needed for manual cuts? These hidden costs add up quickly.

The truth is, the ROI on PPF cutting software often pays for itself faster than you’d think. With better material efficiency, reduced errors, and the ability to serve more customers, the software becomes a cost-saving tool rather than an expense.

“It’s Complicated to Use”

The idea of introducing high-tech software into a shop might feel intimidating, especially if you’re not a tech-savvy person. However, most modern PPF cutting software, like YINK, is designed to be user-friendly. The interface is intuitive, and many software providers offer tutorials, customer support, and even training sessions to get your team up to speed.

If your team can operate a cutting machine manually, they can certainly handle software designed to make their lives easier.

“I Don’t Need It—Manual Cutting Works Fine”

Yes, manual cutting can work. But does it really meet the standards your shop needs to stay competitive? Customers today expect speed, precision, and quality. Manual cutting, no matter how skilled your team, will always be slower and more error-prone than automated software. Investing in PPF cutting software isn’t about replacing your team; it’s about enhancing their capabilities.

The Future of PPF Cutting: Staying Ahead

The automotive industry is evolving rapidly, and PPF cutting software is becoming the standard rather than the exception. In a world where efficiency and precision matter more than ever, staying ahead of the curve is essential for your business to thrive.

By adopting cutting-edge tools like PPF cutting software, you’re future-proofing your shop. As customer expectations rise and competition grows fiercer, having the best tools at your disposal ensures you’re always one step ahead.

Imagine this: A competitor opens up shop down the street offering quicker, more accurate PPF installations because they’ve invested in cutting software. Will your business be able to keep up without the same tools? The reality is that customers gravitate toward businesses that offer the best service—and in today’s world, technology plays a big role in delivering that service.

How to Choose the Right PPF Cutting Software?

So, you’ve decided to invest in PPF cutting software—great choice! But how do you choose the right one? Not all software is created equal, so here are a few factors to consider:

1. Template Library

Look for software with a comprehensive and regularly updated library of car templates. The more models it supports, the more versatile your shop will be. YINK, for example, boasts a robust database that covers everything from luxury sports cars to everyday sedans.

2. Material Optimization

The Super Nesting feature in YINK software is a standout example of how material optimization can save you money. By arranging cutting patterns to maximize every inch of film, you reduce waste and increase profits.

3. Ease of Use

Choose software with an intuitive interface. Your team should be able to learn the system quickly without a steep learning curve.

4. Customer Support

Make sure the software provider offers reliable customer support. Whether you have questions about installation, operation, or updates, having a support team to assist you is invaluable.

5. Scalability

As your shop grows, your tools should grow with you. Opt for software that can handle increased workloads and offers features to support scaling operations.

Real Stories: Shops That Transformed with PPF Cutting Software

Let’s make this discussion more relatable by sharing some real-world success stories:

Case Study 1: The Overwhelmed Shop

A busy suburban automotive shop was struggling to keep up with demand. With multiple cars coming in daily for PPF installations, the manual cutting process became a bottleneck. Customers were frustrated by delays, and technicians were feeling burned out.

After adopting PPF cutting software, the shop saw an immediate improvement. Jobs were completed faster, material waste dropped by 20%, and the team could handle double the workload without additional stress. Customer reviews improved, and referrals skyrocketed.

Case Study 2: The Small Startup

A newly opened shop specializing in luxury cars wanted to differentiate itself from competitors. They invested in YINK software right from the start, positioning themselves as a tech-savvy, high-quality service provider. The decision paid off—clients appreciated the precision and speed of their work, and the shop quickly built a loyal customer base.

In the fast-paced world of automotive care, staying competitive isn’t just about doing good work—it’s about doing exceptional work, efficiently. PPF cutting software gives you the tools to deliver precision, speed, and consistency, all while reducing waste and boosting your bottom line.

Conclusion

Whether you’re running a small startup or managing a high-volume shop, the benefits of PPF Cutting Software are undeniable. From saving time and money to wowing your customers with flawless installations, this technology is an investment that will pay dividends for years to come.

So, what’s holding you back? Take the leap!embrace the future of PPF cutting, and watch your business thrive.

Post time: Dec-05-2024